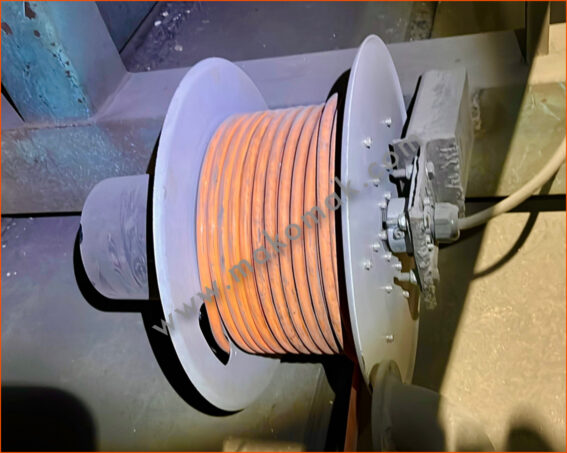

Spring Driven Cable Reels – M-AT1 Series

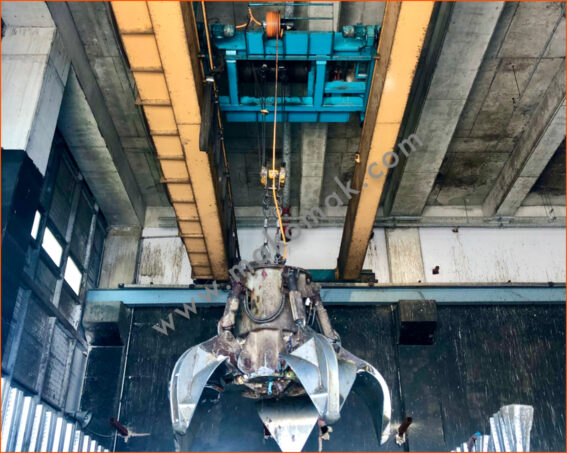

MAKOMAK manufactures a wide range of Spring Driven Cable Reels for industries demands; e.g. grabs, magnets, lifting materials, transfer carts, working platforms, window cleaning systems, portal cranes, waste cleaning system, for vertical and horizontal applications.

All the materials used in the systems designed after market needs with the latest design softwares because we are trying to improve our products. The wearing parts used in the reels are choosen for long-life working, hot dip galvanized side plates and epoxy coating for body prefered in standart apllications. For all parts, Stainles steel can be used if it is needed. The cable reels can be used for applications inside and outside. The housing of the slipring body is protected with the materials carefully choosen.

Standard configurations are always in stock and ready for transport in a week. Special design cable reels can be produced accoring to customer needs and working conditions.

Vertical applications:

The spring driven cable reel can be either placed on the upper mechanism or below on the lifting material also this can be decided accoring to application and also cable dimensions and weight.

Ex. of applications: Portal cranes, transfer carts, water cleaning systems.

Horizontal applications:

The standard winding off the cable is left when looking from the slipring cover side.

When calculating the length of the cable, the installation height must be taken in the considiretion.

Ex. of applications: Portal cranes, transfer carts, water cleaning systems.

Standard features:

The Spring Driven Cable Reels side plates are hot dip galvanized. The reel body is polyester coated. The bolts and nuts used on the reel body is stainless steel and mounting flange and mounting arm bolts are galvanized coated. The slipring cover is plastic or metal accoring to capacities. Working vertical or horizontal in variable measures.

Optional features:

Side plates can be stainles steel or epoxy coated. For special applications, slip ring can be up to 40 poles depending on the amperage. The slipring cover can be sheet metal or plastic. The working length and speed can be adjusted to special applications.

Spring Driven Cable Reel Application Fields:

- ->> Industrial Workshops & Manufacturing Plants

- ->> Sanitation & Waste Water Cleaning Systems

- Mining & Mineral Processing

- Hydraulic & Power Transmission Systems

- ->> Construction Equipment & Infrastructure Projects

- Metal Cutting & Welding Operations

- Chemical & Petrochemical Plants

- Automotive Maintenance & Service Stations

- Static Electricity Control Environments

- Fueling & Refueling Vehicles

- Wind & Renewable Energy

- ->> Shipbuilding & Marine Industry

- ->> Hygienic Food Production & Packaging Lines

- ->> Airport Ground Support Services

- Special Purpose & Utility Vehicles

- Lubrication & Oil Dispensing Systems

- Biopharmaceutical Production

- Fire & Safety Equipment Handling

- ->> Agricultural Machinery & Equipment

- Paper & Pulp Manufacturing

- Landscaping Gardening & Arborist Services

- Highway & Road Maintenance

- Material Handling & Distribution Centers

- Railway Maintenance & Rolling Stock

- Defense & Military Applications

Flange diameters available as standard from 360 to 800mm.

Durable steel frame and drum, protected with industrial grade coating.

Long life springs

Low Voltage (LV) – Slip ring assemblies up to 230V – 690V / up to 300A

Cable guide system ensuring smooth winding and unwinding.

Modular design for spring force and cable length.

Optional stainless steel, galvanized housing for corrosive environments.

Slip Ring Variants – Available for power, control, signal and data transmission including CAT6 and fiber optic.

Cable Types – Wide selection of reeling cabels. Rubber, PUR, reinforced or flame retardent versions.

Housing Materials – Standart powder coating, hot dip galvanized or stainless steel for corrosive environments.

Mounting Styles – Floor, wall, ceiling.

Cable Length & Section – Adaptable to various croos-section and lengths as required.

Protective Accessories – Cable guides, rollers and safety covers.

Low Maintenance – No need for external power, motors or complex drive systems – The spring mechanism ensures long service life with minimal maintenance.

Compact and Durable Design – Robust steel construction with compact dimensions makes them suitable for harsh industrial environments.

Automatic Cable Managment – The spring mechanism keeps the cable properly tensioned and automatically rewinds it, preventing wear, bending and handling errors.

Flexible Installation – Can be mounted in horizontal, vertical or ceiling positions to match different applications.

Safe Operation – Reduces trip hazards and ensures a clean organized working area by keeping excess cable off the ground.

Cost Effective Solution – Energy efficient design with no external drive reduces operational cost compared to motorized reels.

Customizable – Available in various Flange sizes, spring strengths and slip ring configurations to meet specific application needs.